What Goes Into A Bare Knuckle? - Coil Wire

27th September 2022

Wire Types

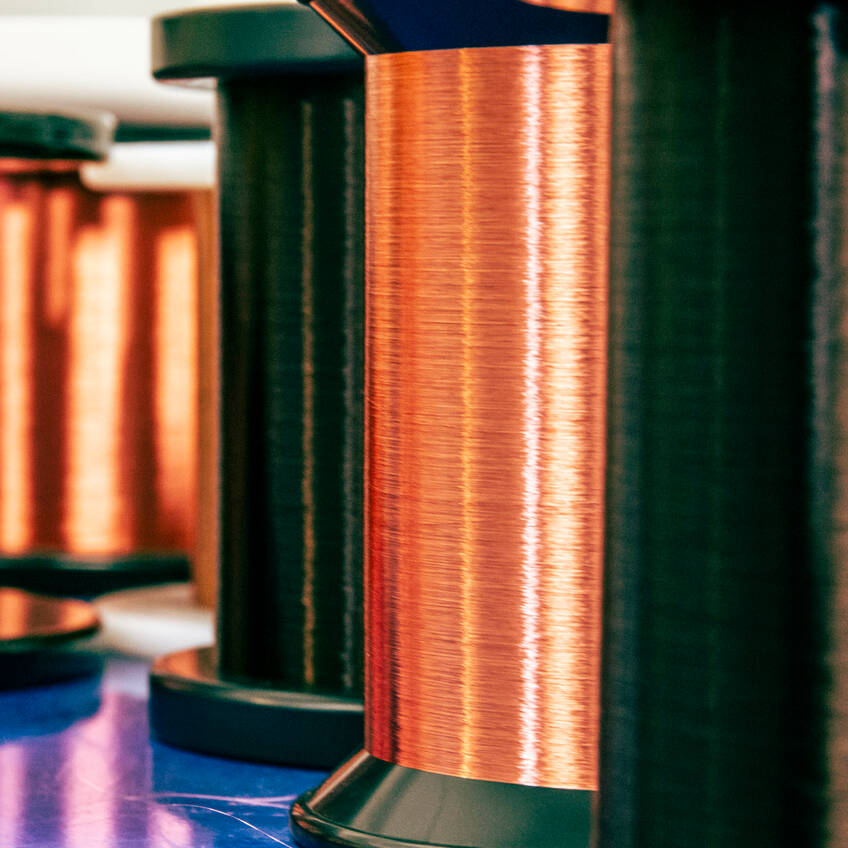

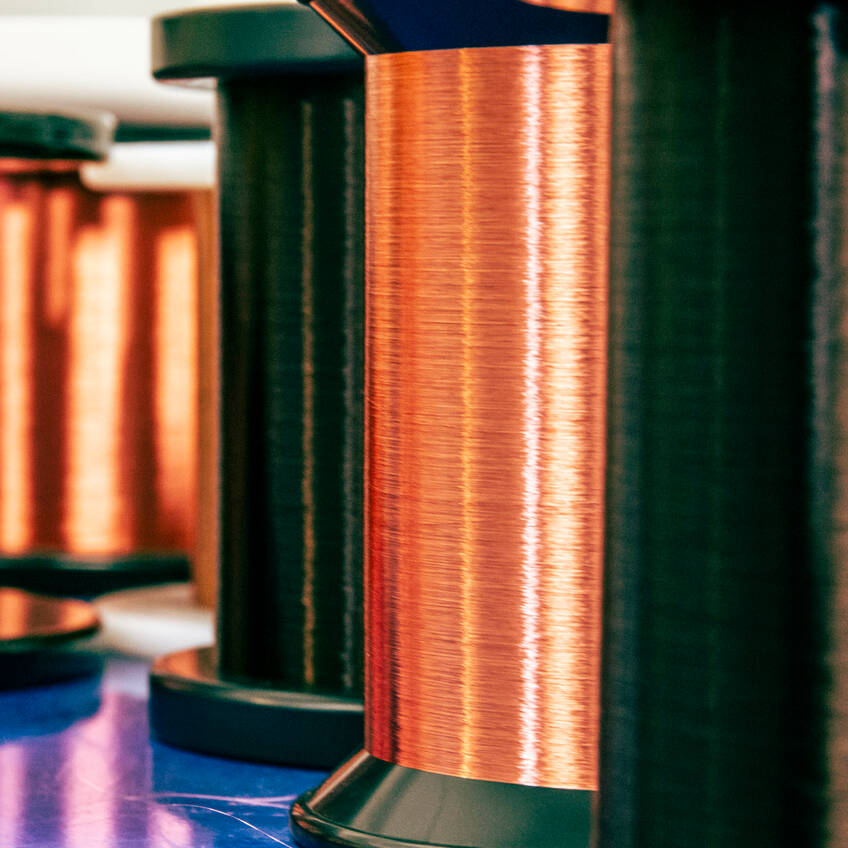

When voicing a pickup set, choosing the right type and gauge of wire is a huge part of what forms the overall sound. We use a broad range of different wires, all of which are based around a coated fine copper wire, but varying in the gauge (diameter) of the wire and also the type of coating used.

Coil wire thicknesses are typically measured using the American Wire Gauge (AWG) scale, with smaller numbers denoting a thicker wire. We typically work between 42 AWG and 45 AWG (0.0635mm - 0.0457mm), so even our thickest wire is still pretty fine! Thicker wires have a lower resistance per metre of length, requiring more turns on the coil to build up a high resistance, so they aren't used in high-output pickups generally, as the coil size required would be too large to fit onto a regular bobbin. As a general rule, this means that as output goes up, wire diameter goes down, but that isn't always the case, which we'll get to in a moment..

The coating on the wire is another important feature. It affects both the amount of insulation between the wraps of wire and also the overall size of the wire, as the AWG number only relates to the inner copper part of the wire, so a thick coating can go a long way towards increasing the overall thickness of the wire and so increasing the size of a given coil. We use 3 main coating types: Formvar / Heavy formvar (formvar is a shortening of "formal varnish", a thermoplastic resin which is coated onto the wire and baked on. "Heavy" formvar denotes a double-layer coating), Plain Enamel (oleoresinous enamel coating; a simple single layer coating which is used in the majority of vintage pickups) and Solderable Polyurethane Nylon or SPN (a more modern polymer coating which can be soldered onto directly).

Coil Wire Gauges and DC Resistance

DC Coil resistance is a very commonly used spec on guitar pickups, denoting the total resistance of the coil(s) of a pickup, often used to describe the output, or how "hot" a pickup is. While it is very commonly referenced, it's also quite problematic, as output is by no means proportional to that number and, in many cases, it's outright misleading! The reason for this is that there are several factors that go into determining how much signal that a pickup will kick out, of which coil resistance is certainly one, but is by no means the only one! Some really good examples within our own humbucker range are the Abraxas bridge and the Black Hawk humbucker. The Abraxas takes a fairly classic P.A.F type spec, with an alnico IV magnet powering it, but steps from the traditional 42AWG to a thinner 43AWG, drastically increasing the coil resistance up to a healthy 14k ohms. However, because the coil dimensions actually decrease, compared to something like our 42AWG Mule humbucker and we keep the same moderately powered alnico IV magnet, the output is only marginally increased, with the main changes occuring within the tonality of the pickup instead. The Black Hawk is the polar opposite, pairing fairly low resistance 42AWG heavy formvar coils with a very focused magnetic field, from its blade style construction, delivering a powerful overall output much closer to a more traditionally built pickup of twice the resistance.

So, how do we decide which is the right wire type and gauge to use for a pickup design?

Well, in the case of more vintage designs, we are often referring to classic combinations and recipes, so that's got a lot more to do with using exactly the right, historically accurate components and specs. With more contemporary designs, it's down to experience; knowing the effects of changing from one gauge to the next and where you will reach the limits of one prticular gauge. The different coatings do have subtly different "flavours" too, with formvar tending to produce an exceptionally clear tone, but plain enamel in the same gauge having a little more grit in the midrange, for example. When there is a specific target in mind for the vibe and tone of a pickup, it's a pretty quick, intuitive decision to get to an approximate combination of wire types and magnets that will send us on the correct path, then our exhaustive R&D process hones that recipe through small tweaks into one of the established (and often award-winning!) pickup models that you will find in our range.